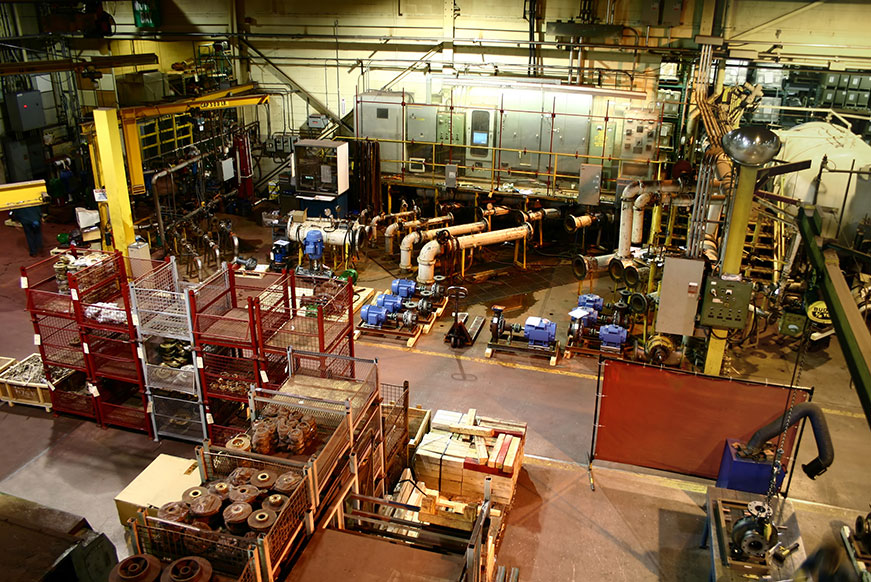

Industrial transformation - Manufacturing - Team Innovation and Team Performance

Functions : Operations, Maintenance, Sales, Logistics, Shipping

The situation from executives and directors standpoint:

• The sales are going down in the aftermath of financial crisis. There is over capacity of production in the market, plants are closing throughout North America.

• Customers are more demanding and will take away business quickly when quality does not meet their expectations.

• Customers taste for color variation in product got beyond normal process capabilities.

• Customers expect quick delivery on all orders placed.

• Inventories must be kept in check to minimize capital frozen in inventories and inventory carrying costs.

• Changes had been made to improve situation without real results.

• The plants are already high performers by North American Standards.

The challenge :

• There was inadequate coordination between all departments involved – Sales – Shipping – Purchasing/Suppliers – Manufacturing – Maintenance

• There was an insufficient amount of teamwork between employees executing the different phases of the business process.

• There was a lack of flexibility in the manufacturing process – high costs of switching product.

• There was inadequate definition of product quality requirements from customers - Lack of focus and tool to control product quality through the process.

• Details of each other roles, needs, work requirements, quality requirements, safety requirements were not clear.

• A missing management system for daily feedback and weekly performance reviews to identify issues, gain support to resolve causes of variances as well as a mean to feedback key information to employees and supervisors.

• Roles, responsibilities and expectations needed to be reviewed to make best use of all resources, to mobilize all resources toward new goals (safety, quality, performance).

The Solution:

• A performance centered diagnostic was conducted, highlighting the wasted resources and the possible gains from systemic management of the operation • A plan was prepared, with initial implementation schedule and completion dates established • Resources were mobilized – to get employees involved and to communicate the challenges. • A Gardner Associates Team coaching approach and process was implemented:

- All teamwork execution was reviewed.

- All roles & responsibilities were reviewed.

- A new Information feedback loop was created and enhanced to share key information with all team members.

- Accelerated learning feedback loop brought information to share with all team members. It allowed adjustments by team all members to improve performance.

- Individual and team training took place with all team members.

- Individual and team coaching took place with all team members.

- A structured coordination between sales, manufacturing and logistics was established

- Customers’ expectations were clarified.

- The manufacturing process was streamlined to overachieve customers’ expectations without capital investment.

- The manufacturing operations were streamlined to maximize performance and reduce costs.

Huge results :

• Week average production increased to reach upward of 92% of theoretical manufacturing capacity; which is manufacturer rated capacity X 24 hours/day.

• The value of products manufactured (due to quality increase) climbed 8% from same raw material.

• The yield on raw material arose to new heights.

• The increased team cohesion allowed for a reduction of turnover costs, quality issues and discipline issues.

• Sales grew as products met and exceeded customer expectations. Orders that previously would have gone to competitors came back to our facility.

• On visit and plant tour, a competitor’s distribution arm purchased our manufactured products to add to theirs: Their own manufacturing could not match quality & prices.

• “LEAN” was implemented: We reduced raw material inventory by 70%,; reduced product change over costs and time by more than 80%. Freeing up cash flow & plant capacity.

• There was an improvement in employees satisfaction and union relations improved due to business stability and advance planning that kept them informed of any coming changes.

• The focus on safety awareness and the LTA prevention showed strong improvement.

• The reduced costs allowed the company to source new markets for lower grade products manufactured.

• Similar training was successfully copied in other divisions with similar .

Business impacts:

• The plant had to add production shifts to cope with demand as competitors were closing more plants.

• The increased product value, yield and performance represented an additional $ 2.3M annually to the bottom line for the division.

• The operating costs were reduced – inventories of raw and finished goods. The labor costs per unit were reduced by 12%.

• The profitability of the operation helped support the entire group, and allowed successful emergence of the group from the financial crisis that affected their clients from 2008 to 2013.

Learn "How we do it". Then practice, find your own way and get our support to build your HIGH PERFORMANCE TEAM and maximize Business Results with TEAMWORK.

Resources – Mining Resources – Mining - Teamwork doubles Team Performance

Scope included : mining development, equipment maintenance, utilities, construction, engineering, logistics

The situation from executives and directors standpoint:

• The mine is developing access to a new rich ore body in the permafrost ground.

• Digging of tunnels started 9 months ago. The current average daily advance is below 6.0 meters/day against the required 7.5 meters/day to maintain schedule.

• Schedule attainment is necessary in order to match with the modifications in progress at the ore processing plant.

• Many attempts and changes had been made to improve performance without any real results.

• The mandate was “performance management” with a goal to reach a daily average advance of 7.5 meters/day.

The challenge :

• There was inadequate coordination between all groups involved – Contractors – Suppliers – Technical services – Mine management and contract oversight.

• There was lack of teamwork between employees executing the different phases of the development – engineering- horizontal development - raises - construction work.

• All decision points for work execution and coordination was concentrated at the supervision / management level.

• Definition of each other roles, needs, work requirements, quality requirements, safety requirements were not clear.

• There was a weak management system to monitor and feedback daily performance, to identify issues and obtain support to resolve causes of variances as well as a mean to feedback key and important information to cross shift.

• All roles, responsibilities and expectations needed to be reviewed to make best use of all resources, to mobilize all forces toward new goals (safety, quality, performance).

The solution :

• A performance centered diagnostic was conducted, highlighting the wasted resources and the possible gains from systemic management of the operation

• A project plan was prepared, the project initial schedule called for the completion after 17 weeks.

• A project management structure was put in place.

• All resources were mobilized.

A Gardner’s Associates Team coaching approach and process was implemented:

• All teamwork execution was reviewed.

• All roles & responsibilities were reviewed.

• Information feedback loop was enhanced.

• Accelerated learning feedback loop brought information to share with all team members.

• Individual and team training took place with all team members

• Individual and team coaching took place with all team members.

Huge results :

• After 5 weeks the week average daily for advance started to climb.

• In week 8 of the project, the week average daily advance reached 7.5 meters/day

• In week 11 of the project, the week daily advance average reached 8.5 meters/day; which was the world record for similar situation (single face development)

• In week 14 of the project, the week average daily advance reached and stabilized at 11.3 meters/day. This average daily advance was maintained until completion of the project.

• In week 15, the mine underground crew was reduced. The development performance and average daily advance remained unchanged.

• The safety awareness and the TRIF showed strong improvement reaching below 6.2 Total Recordable Incidents per million hours worker target.

• The quality of the work done improved, drastically reducing over blasts, eliminating non conformances in scaling, ground support coverage and positioning, in services positioning etc.

• The U/G constructions got to beat estimates, accelerating of facilities, magazines and refuges etc.

The success was part of an article in the Canadian Mining Journal of October 2013.

Two of Canada’s more isolated mines continue to impress

Canadian Mining Journal, October 1, 2013 , by Russell Noble

Business Impact :

• Development for the new mine was completed 6 months ahead of schedule

• Development costs reduced by approximately $4.5 M over the re-forecasted project costs for the Mine operator and Development contractor.

• The development contractor got into position to offer the capacity to offer safe, high quality, accelerated mine development to its clientele. At a performance and a development pace unequalled in the industry.

• The mine operator got in position to improve preparation for optimal mine operation and access to high grade ore body as an important element of strategy to successfully get through the plummeting metals market.